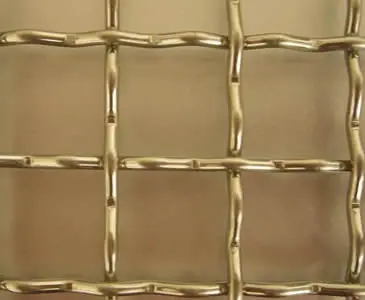

Crimped Wire Mesh

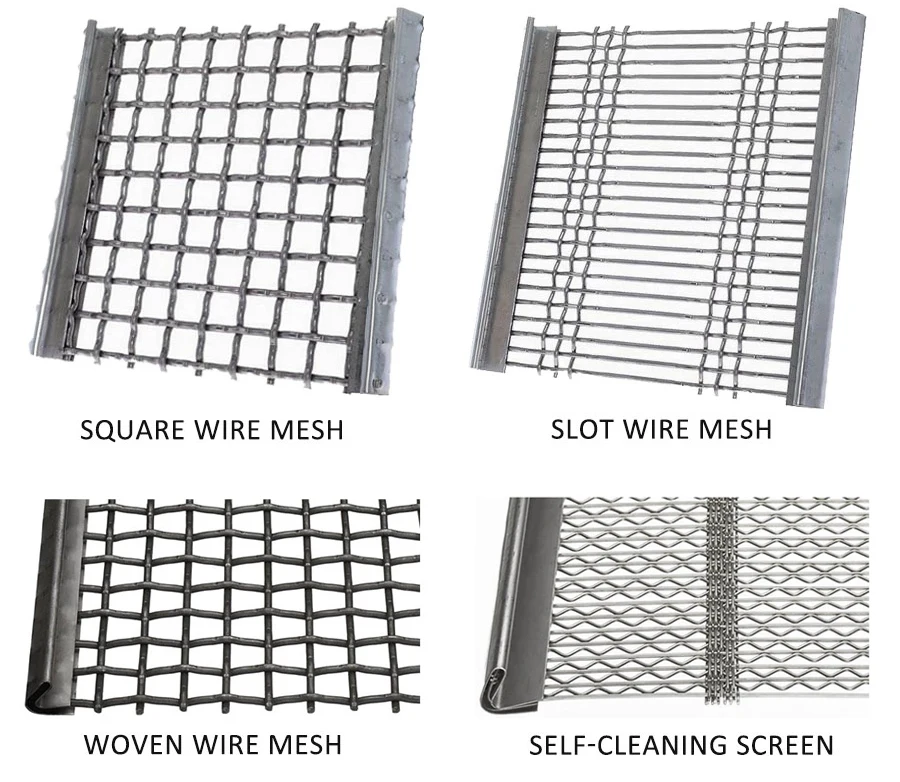

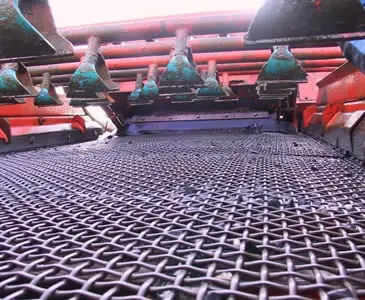

Mining screen, also known as vibrating screen mesh, quarry screen and crusher screen, is one of the most important and versatile parts of screening machines in mining industry, which separates a mix of particles into two or more groups depending on size and is widely used in a variety of sizing, grading, scalping, dewatering, wet screening and washing applications.

Advantage:

1.High mechanical strength, large carrying capability

2.High abrasion and chemical corrosion resistance

3.Excellent vibration and impact resistance

4.Large screening area

5.A long service life

Application:

|

Item

|

Crimped wire mesh

|

|

Place of Origin

|

Hebei, China

|

|

Technique

|

Woven

|

|

Features

|

Corrosion/Acid resistant, alkali resistant

|

|

Uses

|

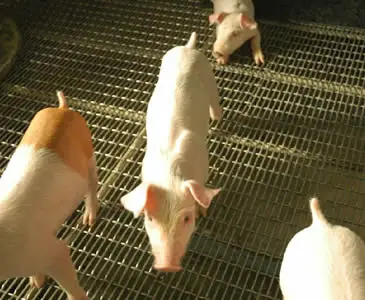

Mine, petroleum, chemical, food, Breeding industry

|

|

Material

|

304 304L 316 316L

|

|

Hole shape

|

Square Hole or rectangle

|

|

Edge type

|

Plain, bent and reinforced hooked

|

|

Physical size

|

Wide(0.5-2m) Length( 5-50m) as per customer request

|

|

Wire Diameter

|

0.1-10mm or as per customer request

|

|

Delivery time

|

20 days after receiving the deposit

|

|

Package

|

Waterproof Paper +Paper Carton+Wooden box

|

Various Types

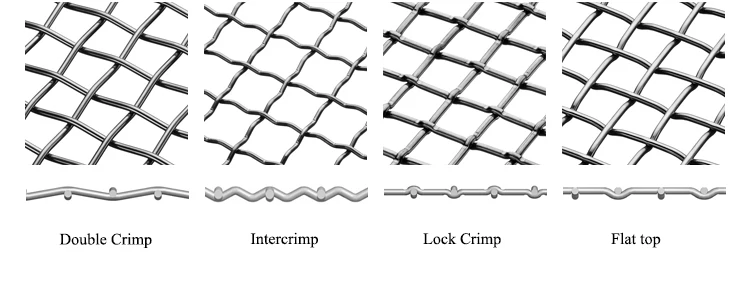

Flat top crimped, also called pressed crimped, is made from round and profiled plain weave wire. All the mesh knuckles is being on the underside. The structure is very heavy and durable. The smooth surface is the characteristic of the weaving method. This structure can allow the materials to move more freely over the screen. It is widely used in the vibrating screen.

Lock crimped is a refinement of the intermediate crimped. It can lock the wire at their position through pressed at each side of the raised wire. This structure can add the stability of the crimped woven wire mesh.

Intermediate crimped can be divided into single intermediate crimped and double intermediate crimped.

The single intermediate crimped means the weft wire is pre-crimped and the warp wire is directly woven. The double intermediate crimped means both the weft wire and warp wire is pre-crimped and then woven together.

Double crimped is also called plain weave. Different from the intermediate crimped, both the warp wire and weft wire are woven directly by straight wire. We can get a rigid construction through evenly crimp in warp and weft wire. This is used mainly with lighter wires to ensure tension in a light screen.

Product Applications

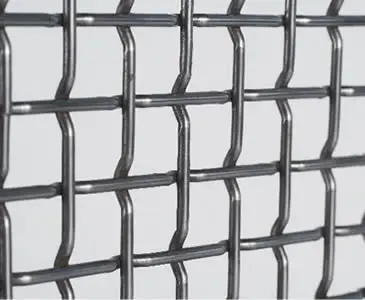

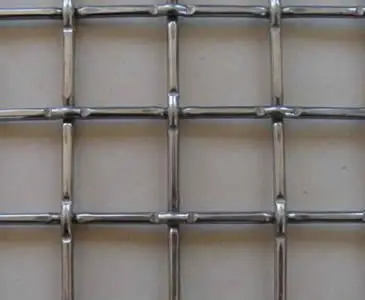

Stainess Steel Crimped Wire Mesh can be also known as the iron crimped mesh, stainless steel crimped mesh, black iron crimped mesh according to different materials.

Crimped Wire Mesh is made in a variety of materials through crimping mesh machine, a kind of universal wire products with square or rectangular openings.

Crimped Wire Mesh Material: Iron wire, black wire, stainless steel wire, copper wire and other non-ferrous metal.

Weaving: Pre-crimping before Weaving. In two-way separated wave bending, locked bending, flat-topped curved, two-way bending, one-way separated wave bending.

Features: Structure firm and durable.

Uses: Used for mining, coal plants, construction, petrochemical industry, construction machinery, etc.

| Wire Gauge SWG |

Wire Diameter |

Mesh/Inch |

Aperture mm |

Weight kg/m2 |

| 14 |

2.0 |

21 |

1 |

4.2 |

| 8 |

4.05 |

18 |

1 |

15 |

| 25 |

0.5 |

20 |

0.61 |

2.6 |

| 23 |

0.61 |

18 |

0.8 |

3.4 |

| 24 |

0.55 |

16 |

0.1 |

2.5 |

| 24 |

0.55 |

14 |

0.12 |

4 |

| 22 |

0.71 |

12 |

0.14 |

2.94 |

| 19 |

1 |

2.3 |

0.18 |

1.45 |

| 6 |

4.8 |

1.2 |

2 |

20 |

| 6 |

4.8 |

1 |

2 |

20 |

| 6 |

4.8 |

0.7 |

3 |

14 |

| 14 |

2.0 |

5.08 |

0.3 |

12 |

| 142. |

2.0 |

2.1 |

1 |

2.5 |

| 14 |

2.0 |

3.6 |

1.5 |

1.9 |

Crimping Styles