Stainless steel Crimped wire Mesh raw material is selected for their wear-resisting, heat-resisting, acid-resisting and corrosion resisting characteristics. Many different grades of stainless are used in wire cloth. T304 is the most common

Wire Materials: SUS302, 304, 316, 304L, 316L.

Characteristics: Square aperture, less rigid than plain weave, especially suitable for deforming, strong

wire cloth due to ratio of wire diameter and aperture, it is mostly used for filtration less than 63 μm .

Stainless steel wire meshTypical Weaving Patterns: Plain weave, twill weave, dutch weave.

1. Material: Galvanized iron wire,or stainless steel wire

2. Surface treatment: Electro galvanized or hot dipped galvanized

3. Application: Used in industries and constructions to sieve grain powder,filter liquid and gas,safety guards on machinery enclosure.wood strips in making wall and ceiling

|

Wire Gauge

SWG

|

Wire Diameter mm

|

Mesh/Inch

|

Aperture

mm

|

Weight

Kg/m2

|

|

14

|

2.0

|

21

|

1

|

4.2

|

|

8

|

4.05

|

18

|

1

|

15

|

|

25

|

0.50

|

20

|

0.61

|

2.6

|

|

23

|

0.61

|

18

|

0.8

|

3.4

|

|

24

|

0.55

|

16

|

0.1

|

2.5

|

|

24

|

0.55

|

14

|

0.12

|

4

|

|

22

|

0.71

|

12

|

0.14

|

2.94

|

|

19

|

1

|

2.3

|

0.18

|

1.45

|

|

6

|

4.8

|

1.2

|

2

|

20

|

|

6

|

4.8

|

1

|

2

|

20

|

|

6

|

4.8

|

0.7

|

3

|

14

|

|

14

|

2.0

|

5.08

|

0.3

|

12

|

|

14

|

2.0

|

2.1

|

1

|

2.5

|

|

14

|

2.0

|

3.6

|

1.5

|

1.9

|

Heavy industrial screens vibrating screen wire mesh is available in different wire diameters, mesh opening and open area. This is widely used for various applications such as screening, sizing, grading, shifting, separating, scalping and washing. This wire mesh can be also custom designed in case plungers and vibrating rods are needed to insert for protection against tearing. It is installed above rubber beads to avoid metal to metal contacts.

|

Name

|

SUS 304 316 316l 6 8 10 12 14 20 mesh stainless steel crimped woven wire mesh

|

|

High carbon steel:

|

65Mn,45#,50#,55#,60#,70#,72A, 304, 316, 316L

|

|

Wire diameter

|

0.8mm-12.7mm,Our finished wire is inspected by third party SGS,Tolerance+_0.03mm.

|

|

Aperture/Opening

|

2mm to 100mm,tolerance +-3%

|

Features:

1.No tearing and abrasion

2.Placed above rubber beads to avoid metal to metal contact

3.Corrosion resistance

4. High temperature resistance

IMPORTANT FACTS TO CONSIDER WHEN ORDERING SCREENS:

When screens form part of the manufacturing process, the profits will depend on the specification of the screens which must be chosen to give optimum performance. The specification of the screen best suited to the screening operation depends on:

The screen selected must achieve a compromise amongst these factors.

When ordering screens the following technical aspects should be taken into account :

Thickness of wire

Thick wire will last longer than thin wire, but will give a smaller open area and will therefore pass less material per unit area.

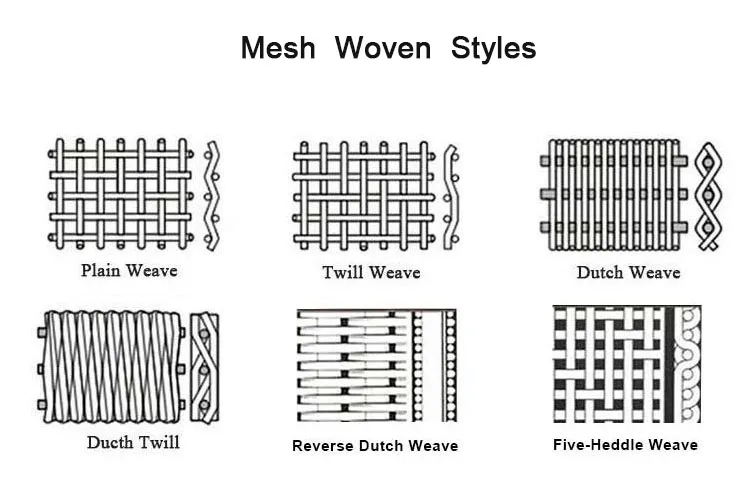

Our factory can provide many different weaves to meet different application needs. the weave styles mainly depend on the mesh and wire diameter specifications of the woven mesh. below are the show of some common styles :

Stainless steel wire mesh Plain weave :every warp wire across every weft wire ,the warp wire and weft wire diameter is same and the warp wire and weft wire showing 90°degree .

Stainless steel wire mesh Twill weave :every warp wire across per two weft wire ,every weft wire across per two warp wire .

Stainless steel wire mesh Dutch weave: the warp wire is thicker and the weft wire is thinner .

| Stainless Steel Square Woven Mesh |

| Weave |

Mesh |

Wire Dia. |

Width of Opening |

Open Area |

Weigh Per 100 sq' |

Opening |

| Type |

Count |

(Inch) |

(Inch) |

(%) |

based on 304ss |

(Micron) |

| Plain |

2 x 2 |

0.063 |

0.437 |

76.4 |

51.7 |

11119 |

| Plain |

3 x 3 |

0.054 |

0.279 |

70.1 |

57.3 |

7099 |

| Plain |

4 x 4 |

0.047 |

0.203 |

65.9 |

58.2 |

5165 |

| Plain |

5 x 5 |

0.041 |

0.159 |

63.2 |

55.4 |

4046 |

| Plain |

6 x 6 |

0.035 |

0.132 |

62.7 |

48.6 |

3359 |

| Plain |

6 x 6 |

0.032 |

0.135 |

65.6 |

20.7 |

3435 |

| Plain |

7 x 7 |

0.032 |

0.111 |

60.4 |

47.5 |

2824 |

| Plain |

7 x 7 |

0.028 |

0.115 |

64.8 |

36.2 |

2926 |

| Plain |

8 X 8 |

0.025 |

0.1 |

64 |

32.9 |

2545 |

| Plain |

9 X 9 |

0.025 |

0.086 |

59.9 |

37.3 |

2188 |

| Plain |

9 X 9 |

0.023 |

0.088 |

62.7 |

31.4 |

2239 |

| Plain |

10 x 10 |

0.025 |

0.075 |

56.3 |

41.6 |

1908 |

| Plain |

11 x 11 |

0.023 |

0.068 |

56 |

38.8 |

1730 |

| Plain |

11 x 11 |

0.02 |

0.071 |

61 |

29.1 |

1807 |

| Plain |

12 x 12 |

0.02 |

0.063 |

57.2 |

31.9 |

1603 |

| Plain |

14 x 14 |

0.02 |

0.051 |

51 |

37.6 |

1298 |

| Plain |

16 x 16 |

0.018 |

0.0445 |

50.7 |

34.8 |

1132 |

| Plain |

18 x 18 |

0.017 |

0.0386 |

48.3 |

35.1 |

982 |

| Plain |

20 x 20 |

0.02 |

0.03 |

36 |

55.8 |

763 |

| Plain |

30 x 30 |

0.012 |

0.0213 |

40.8 |

29.7 |

542 |

| Plain |

30 x 30 |

0.0095 |

0.0238 |

51 |

18.2 |

606 |

| Plain |

40 x 40 |

0.01 |

0.015 |

36 |

27.9 |

382 |

| Plain |

50 x 50 |

0.0055 |

0.0145 |

52.6 |

10.1 |

369 |

| Plain |

60 x 60 |

0.006 |

0.0107 |

41.2 |

14.8 |

272 |

| Plain |

60 x 60 |

0.0045 |

0.0122 |

53.3 |

8.1 |

310 |

| Plain |

80 x 80 |

0.0055 |

0.007 |

31.4 |

17.1 |

178 |

| Plain |

100x100 |

0.0045 |

0.0055 |

30.3 |

14.3 |

140 |

| Plain |

100x100 |

0.004 |

0.006 |

36 |

11.1 |

153 |

| Plain |

120x120 |

0.0026 |

0.0058 |

47.3 |

5 |

148 |

| Plain |

150x150 |

0.0026 |

0.0041 |

37.4 |

7.2 |

104 |

| Plain |

165x165 |

0.0019 |

0.0042 |

47.1 |

4.2 |

107 |

| Plain |

180x180 |

0.0023 |

0.0033 |

34.7 |

7.5 |

84 |

| Plain |

200x200 |

0.0019 |

0.003 |

60.6 |

3.6 |

77 |

| Plain |

230x230 |

0.0014 |

0.0029 |

46 |

3.4 |

74 |

| Plain |

250x250 |

0.0016 |

0.0024 |

36 |

4.3 |

61 |

| Twill |

270x270 |

0.0016 |

0.0021 |

32.2 |

4.8 |

53 |

| Plain |

300x300 |

0.0012 |

0.0018 |

29.7 |

3 |

46 |

| Twill |

325x325 |

0.0014 |

0.0017 |

30 |

4.3 |

43 |

| Twill |

400x400 |

0.0011 |

0.0014 |

31.4 |

3.4 |

36 |

| Twill |

500x500 |

0.001 |

0.001 |

25 |

* |

25 |

| Twill |

635x635 |

0.0008 |

0.0008 |

25 |

* |

20 |

Stainless steel wire mesh with its excellent resistance against acid, alkali, heat and corrosion, find extensive uses in processing of oils, chemicals, food, pharmaceuticals, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace, machine making, etc

Stainless steel wire mesh with its excellent resistance against acid, alkali, heat and corrosion, find extensive uses in processing of oils, chemicals, food, pharmaceuticals, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace, machine making, etc

For Architectural Application:Woven Wire Mesh Fence,Wire Mesh Ceiling,Wire Mesh Wall Cladding

For Wire Mesh Screen:Stainless Steel Fireplace Screen,Window Insect Screen Mesh

For Food Grade Application:Wire Mesh Grain Sieve,Liquid (Coffee) Filters,Food Strainer & Sieve

For Industrial Filter:Filter Element,Sintered Filter Screen,Stainless Steel Speaker Grill

Edge types of the Crusher vibrating screen:

Heavy industrial screens vibrating screen wire mesh is available in different wire diameters, mesh opening and open area. This is widely used for various applications such as screening, sizing, grading, shifting, separating, scalping and washing. This wire mesh can be also custom designed in case plungers and vibrating rods are needed to insert for protection against tearing. It is installed above rubber beads to avoid metal to metal contacts.

Name

SUS 304 316 316l 6 8 10 12 14 20 mesh stainless steel crimped woven wire mesh

High carbon steel:

65Mn,45#,50#,55#,60#,70#,72A, 304, 316, 316L

Wire diameter

0.8mm-12.7mm,Our finished wire is inspected by third party SGS,Tolerance+_0.03mm.

Aperture/Opening

2mm to 100mm,tolerance +-3%

Features:

1.No tearing and abrasion

2.Placed above rubber beads to avoid metal to metal contact

3.Corrosion resistance

4. High temperature resistance

IMPORTANT FACTS TO CONSIDER WHEN ORDERING SCREENS:

When screens form part of the manufacturing process, the profits will depend on the specification of the screens which must be chosen to give optimum performance. The specification of the screen best suited to the screening operation depends on:

The screen selected must achieve a compromise amongst these factors.

When ordering screens the following technical aspects should be taken into account :

Thickness of wire

Thick wire will last longer than thin wire, but will give a smaller open area and will therefore pass less material per unit area.

Edge types of the Crusher vibrating screen:

Detailed images

SUS 304 316 316l 6 8 10 12 14 20 mesh stainless steel crimped woven wire meshSUS 304 316 316l 6 8 10 12 14 20 mesh stainless steel crimped woven wire meshSUS 304 316 316l 6 8 10 12 14 20 mesh stainless steel crimped woven wire meshSUS 304 316 316l 6 8 10 12 14 20 mesh stainless steel crimped woven wire mesh

Packaging & Shipping

SUS 304 316 316l 6 8 10 12 14 20 mesh stainless steel crimped woven wire mesh

Company Information

https://ropemesh.com.au/

BOSS METAL is a professional manufacturer of all kinds of wire mesh filtering. Our company was established in 2004 and we have many year of history in the wire mesh industry.

Our main products are stainless steel wire mesh, nickel and nickel alloy wire mesh, heating resisting wire mesh and processed mesh products like filter packs and tubes. These products are widely used in the industries of oil, chemicals, food, pharmaceuticals, machine making, scientific research, marine engineering, chemical and hydro-carbon processing equipment, heat exchangers, valves, pumps, etc.

Our products are sold well in Europe,Southest Asia,Africa ,American countries etc and won the trust both home and abroad. Our company is of the advantage of locating “the land of wire mesh”, we have advanced equipments and our technological process is perfect.

The policy is “to be honest and creditable”. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyer s to contact us.